The Future of Field Service is Now

I’ve seen the future of field service—and it’s proactive.

While the technology that companies use to service customer issues has certainly advanced over the years, the basic model for field service has remained largely unchanged—whether the product is a front-loading washing machine or a fifty-ton hydraulic press. A customer calls to report a problem, and a technician is dispatched to try to solve it. It’s inefficient. It’s costly. It’s reactive. But, until now, it was the best companies could do.

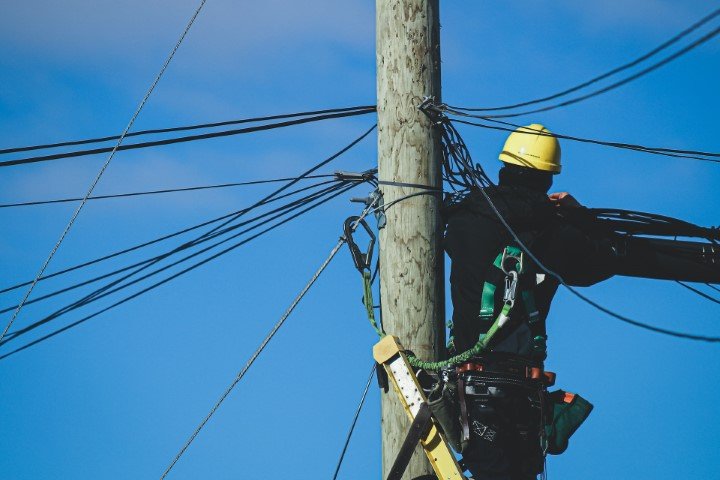

With the convergence of the Internet of Things (IoT) and wearable technologies, however, field service organizations can solve problems before their customers even know they exist (one of my three top initiatives for field service in 2015). Sensors embedded in machines alert the servicing center that something is about to go wrong. By combining that machine data with advanced analytics, that alarm is immediately converted to a job order that is then automatically assigned to a qualified nearby technician which pops up on his smartwatch or mobile device along with directions to the customer location. Once on site, the field service professional slips on his smart glasses, which direct him to the source of the trouble and deliver a schematic to guide him through the issues resolution. If he hits a snag, it’s no problem. He simply taps his headset to connect to an expert back at headquarters to talk him through a fix.

Thanks to more robust data analytics tools combined with IoT and wearable, such a scenario is no longer the stuff of fantasy. And these technologies can deliver real ROI.

The Right Technician, The Right Part, The Right Time

More than half (51 percent) of the second field service visits are the result of not having the right parts available the first time, according to a 2013 report by Aberdeen Research; one quarter of the time, a second trip is necessary because the technician lacked the knowledge to make the fix the first time. Thanks to IoT and wearables, companies will be able to send the right technician to the right job armed with the right parts and knowledge on the first try. With this more insightful data, they might even avoid sending someone to a customer site at all if there is a remote fix to remedy the problem. The resulting savings can add up quickly. It costs $1,000 on average to dispatch a field service professional onsite (known in the industry as a “truck roll”), according to the Technology Services Industry Association (TSIA).

Leading companies as varied as computer chip makers, food and beverage companies, and manufacturers of copiers already begin to adopt these tools successfully to streamline their field service operations and take a more proactive approach to customer service.

As companies accumulate more data from connected products and field service calls, they can use predictive analytics to schedule preventive maintenance more strategically or share data with R&D groups to improve product development. Ultimately, IoT and wearables in field service could have top line benefits as well—whether it’s charging for performance-based service or longer up-time. Most importantly, these interconnected technologies will be a critical enabler for a better customer engagement —which is fast becoming the competitive differentiator for forward-thinking companies.

This blog originally published on The Customer Edge